Lubrication in wind turbines is not a luxury; it’s a critical part of the system designed to reduce friction, prevent wear, and protect components from environmental damage. Let’s take a closer look at why lubrication is absolutely necessary for turbines to operate efficiently in extreme weather conditions:

Wind turbines are made up of many moving parts that experience intense friction during operation, particularly in the gearbox and the bearings. Friction generates heat, which in turn leads to wear and tear. In extreme weather, this friction can become even more damaging. For instance, in freezing temperatures, without proper lubrication, metal components could expand or contract in ways that increase friction.

Lubricants form a protective layer between these moving parts, drastically reducing the friction and wear that can otherwise occur. When a wind turbine operates smoothly, it experiences less strain, leading to improved energy efficiency and reduced maintenance costs.

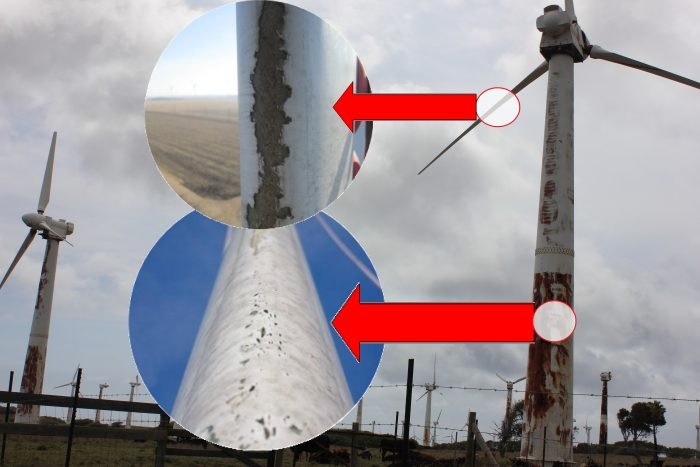

Rain, snow, and humidity can wreak havoc on the metal components inside a wind turbine. Left unchecked, moisture can cause metal parts to rust and corrode, which compromises their structural integrity. For example, water intrusion in the gearbox can lead to the breakdown of oil, resulting in friction, overheating, and component failure.

Lubrication, especially those designed for extreme conditions, act as a protective barrier. They help prevent moisture from coming into direct contact with vulnerable parts, shielding the metal from corrosion and extending the life of critical components. Without these protective lubricants, turbines would be much more vulnerable to weather-related damage, leading to costly repairs and downtime.

Extreme temperatures, both hot and cold, pose a significant challenge to wind turbine efficiency. When temperatures drop below freezing, lubricants can become too thick, leading to sluggish performance or even mechanical failure. On the other hand, when temperatures rise, lubricants can break down and lose their ability to lubricate effectively.

Specialized lubricants are formulated to remain stable across a wide range of temperatures. These lubricants ensure that even in freezing cold or intense heat, the turbine’s moving parts stay properly lubricated, reducing the risk of failure due to overheating or cold-related issues. This temperature regulation keeps the turbine running at peak performance regardless of weather conditions, thereby optimizing energy production.

Ice buildup on the blades of wind turbines is one of the most severe weather-related challenges. As the blades accumulate ice, their aerodynamic properties are compromised, leading to a loss of efficiency. More critically, ice can cause additional strain on the pitch system and bearings, which are responsible for adjusting the angle of the blades to maximize energy capture.

Lubrication plays a key role in preventing excessive ice buildup on turbine blades and internal components. In addition to lubricating the mechanical parts, special lubricants are designed to resist the formation of ice, ensuring smoother operations even in freezing conditions. By preventing the friction that could otherwise lead to the formation of ice, lubrication helps mitigate the damage that freezing weather can cause to wind turbines.

Wind turbines are often located in remote areas, which can make maintenance and repairs difficult and costly. The farther a turbine is located from urban areas, the more expensive and time-consuming repairs become. Regular maintenance costs can add up significantly over time, especially if turbines fail prematurely due to environmental stress.

By using ANSWRS lubrication systems designed for extreme conditions, turbines experience less wear and tear, which results in longer intervals between maintenance cycles. This reduces downtime, increases the operational lifespan of the turbine, and ultimately saves on repair costs. Lubrication can help ensure that turbines are ready to perform at their best, year-round.